Common knowledge of hard alloy cutting tools

Writer: admin Time:2024-06-19 11:45:58

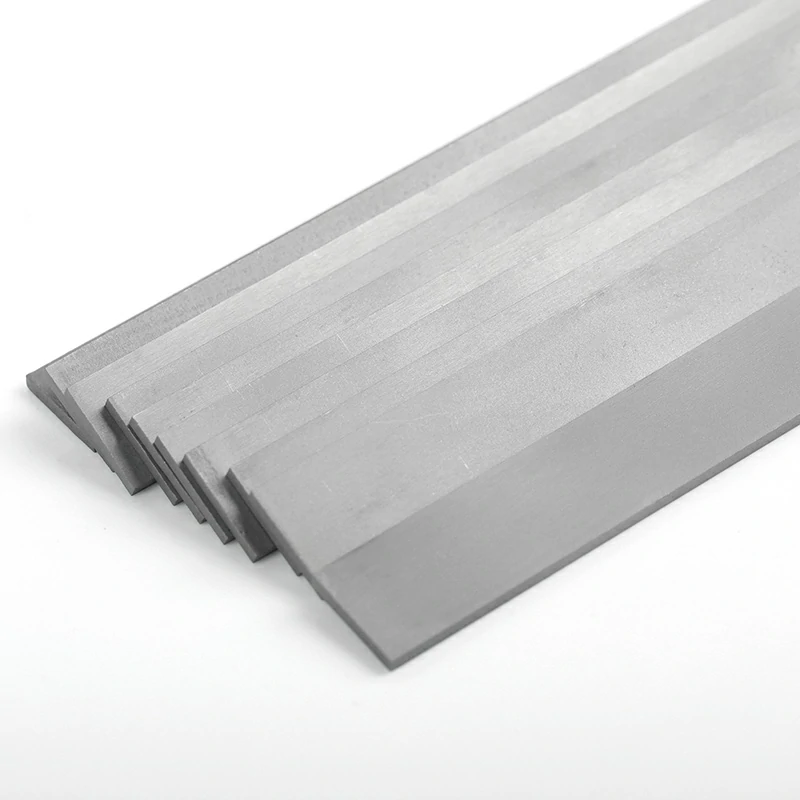

Hardness and strength of carbide tools

Hardness refers to the elastic limit of a metal, and its value is related to the composition of the alloy, the processing conditions, and the method of use.

Generally take HV10H (Shore Vitus alloy) as an example, when its hardness value is HV50, the corresponding elasticity limit is 1.

The elastic limit corresponds to 1 at a hardness value of HV50. As the cobalt content increases, the strength and hardness increase. The strength is higher when the cobalt content is between 5%~20%; the hardness is highest when it is between 25%50% and the strength decreases when it exceeds 50 %.

Generally, when the use temperature is higher than 800℃, the brittleness phenomenon of metal materials begins to appear.

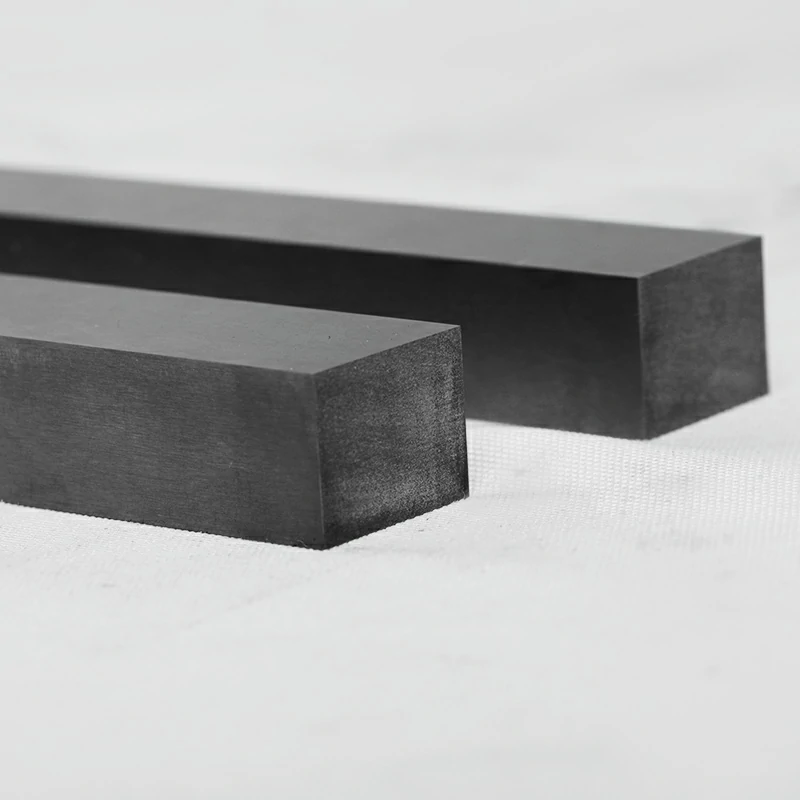

Main parameters of carbide cutting tools.

The main parameters include hardness, elastic limit, hardenability, and wear resistance.

1. Hardness: Take HRC40-60 as an example, the hardness when the hardness is HRC45-50, refers to the amount of elastic deformation in the metal material, which is the elastic limit of the alloy. The main parameters of cobalt-containing cemented carbide inserts are hardness: A120-40, and D25-30, for example. HV50, which corresponds to the elastic limit of 0.35 ± 0.01σ (-0.1) σ; cobalt-containing cemented carbide inserts of hardness: HV50-570, which corresponds to the elastic limit of 0.04 ± 0.02 σ; cobalt-containing cemented carbide inserts with the strength, hardness than HV50 increased by 2 times Above.

2. Elastic limit: take D25-30 as an example.

3. Determination of hardenability of cemented carbide inserts: At room temperature, cold oil of 10℃/min is flowed into the cemented carbide inserts, and the hardness is measured as 50 HRC. after quenching, the surface of the cemented carbide inserts is smoothed by a grinding machine or grinding wheel, and then the workpiece is put in the furnace of 500℃~600℃ to be quenched and hardened. A large amount of hardened layer remaining in the workpiece cannot be ground flat and should be removed, otherwise it will affect the service life of the tool. After sintering at 1000~1500℃ for 20 min, the workpiece is treated with quenching (at 1000℃) and then ground. Grinding and deburring processes should be carried out after grinding.

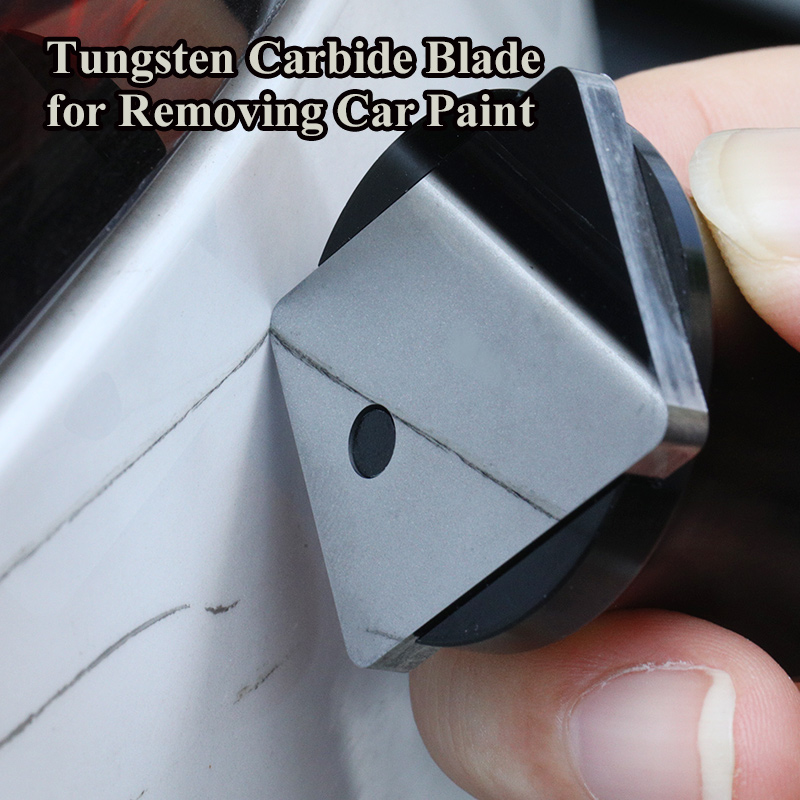

Cemented carbide cutting tools maintenance and machining

Cutting dosage.

Carbide inserts in the grinding process should be strictly to the requirements of the selection of appropriate cutting dosage. If machining with an ordinary turning tool, the chips will be pulled off due to the cutting force; if grinding with a high-speed turning tool, the chip will be impacted and vibrated by the high-speed movement of the chip and produce the phenomenon of chipping; if machining the workpiece with a cemented carbide insert, try to choose the large-size and high-precision cutting tool and toolpost, and use high-speed steel cutting tool, and appropriately increase the flow rate of the coolant; try to use the low-speed cutting in the machining (such as a no-load operation). The following points should also be noted:

l In processing, remove the chips on the back of the tool and the tip of the tool promptly;

l Try not to rinse the tool directly with water on the workpiece, which makes it easy to make the residual liquid adhere to the tip of the tool and the back of the tool;

l When the carbide inserts are cracked, the inserts should be replaced promptly;

l The life of the tool increases with the prolongation of the use of time, to prolong the life of the tool, it can be used to appropriately increase the thickness of the hardened layer or use a carburizing process to prolong the life of the tool.