Products Description

Classification of molybdenum crucibles

Types of molybdenum crucibles: Machined crucibles, sintered crucibles, spun crucibles, stamped crucibles, etc.

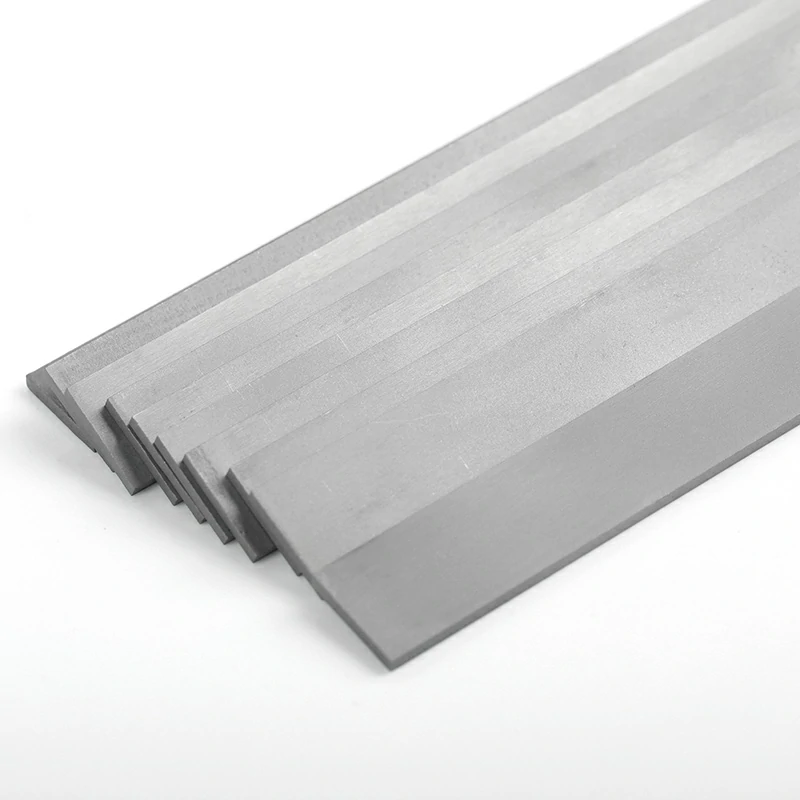

Machined molybdenum crucibles |

Purity | Density | Specification | Tolerance | wall thickness (mm) |

99.95% | ≥10.2g/ cm3 | D(mm) 10-100 | H(mm) 10-200 | T +/-5.0 | H +/-5.0 | 1-20 |

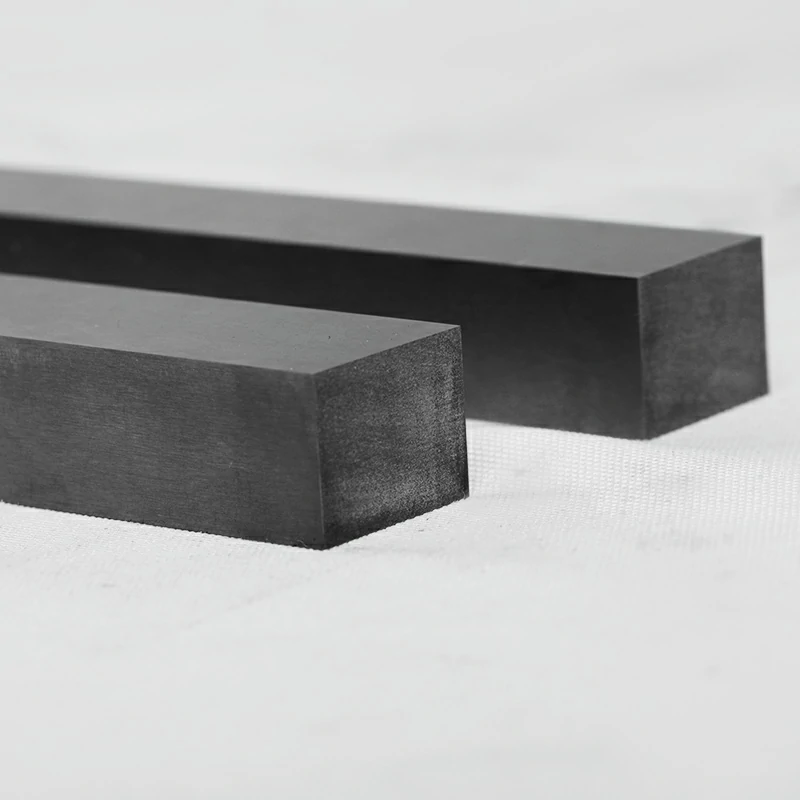

Sintered molybdenum crucibles |

Purity | Density | Specification | Tolerance | Wall thickness | Surface roughness |

99.95% | ≥9.8g/ cm3 | Diameter (mm) 100-600 | Height (mm) 100-1000 | T +/-0.5 | H +/-1.0 | 8-20 | Ra=1.6 |

Spinning Molybdenum Crucibles |

Grade | Purity | Place of Origin | Impurity Content |

Mo-1 | 99.95+ (%) | China | 0.05 or less (%) |

A brief introduction of Moly crucible

The molybdenum crucible is produced using Mo-1 molybdenum powder and is used at temperatures from 1100°C to 1700°C. It is mainly used in the metallurgical industry, rare earth industry, monocrystalline silicon, solar energy, artificial crystals and mechanical processing.

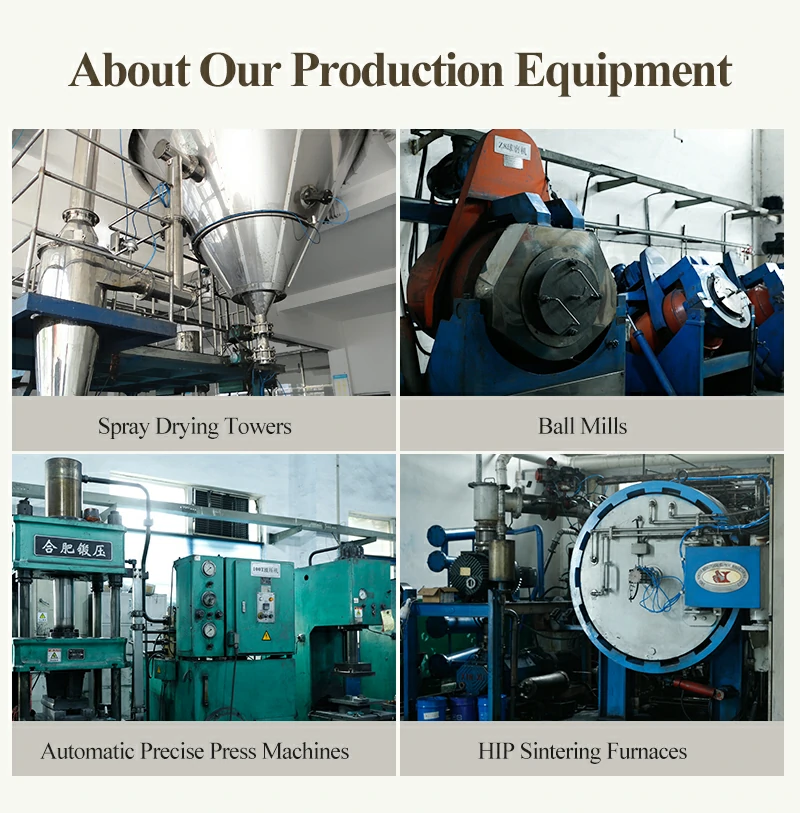

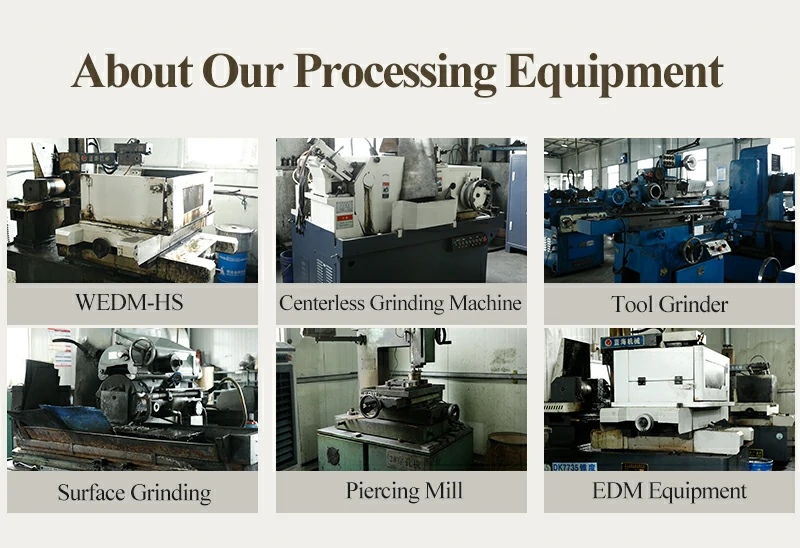

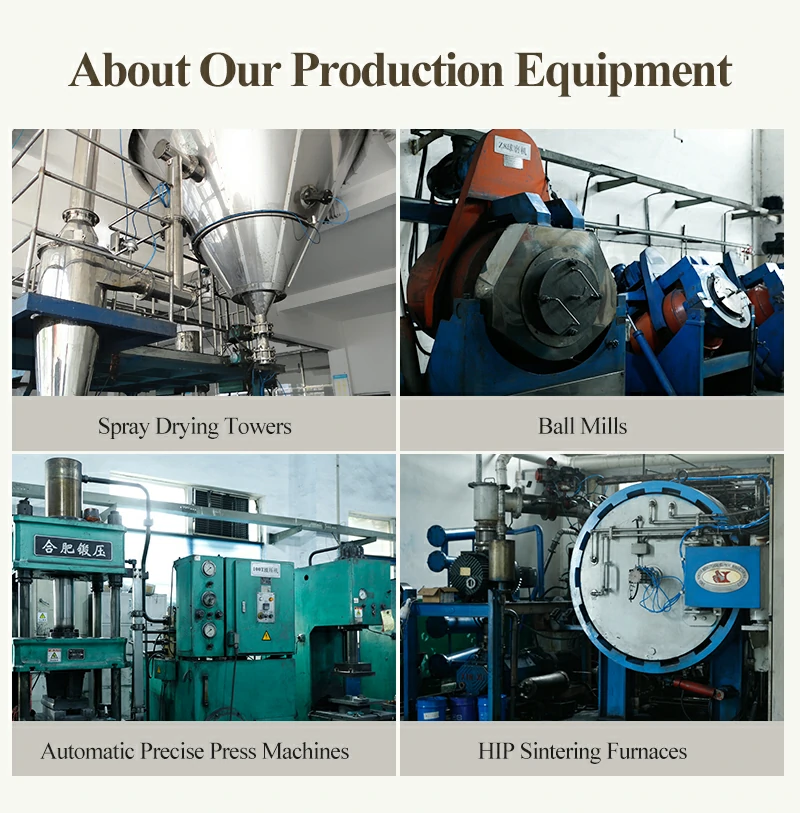

Production process of molybdenum crucibles

Molybdenum powder - Sieving - Blanking - Isostatic pressing - Rough turning - Medium frequency sintering - Fine turning - Packaging

Applications for molybdenum crucibles

Due to its high melting point of 2610°C, molybdenum crucibles are widely used as core containers in industrial furnaces such as sapphire single crystal growth furnaces, quartz glass melting furnaces and rare earth smelting furnaces, where the working temperature environment is generally above 2000°C. Especially for sapphire single crystal growth furnaces, the molybdenum crucible with its high purity, high density, no internal cracks, precise dimensions, smooth inner and outer walls, etc. plays a key role in the success rate of the seed crystal, the quality control of the drawn crystal, the de-crystallisation of the sticking pot and the service life of the sapphire crystal growth process.

Company Profile