How Carbide Rings End Wear Challenges in Industrial Pump Rotating Parts?

Writer: admin Time:2025-12-23 16:12:59

A Sand-Sized Problem with Oversized Costs

At a major Australian chemical plant, trace sand particles in cooling water were causing relentless damage to circulation pumps. Each tiny grain acted like a miniature cutting tool, wearing down internal components during high‑speed operation. The result? Frequent failures, unplanned downtime, and mounting costs.

Why Traditional Materials Failed

The original stainless steel sleeves simply couldn’t withstand the abrasive environment. Within just three months, excessive wear would increase clearances, cause vibration, and force a shutdown. This cycle of replacement and repair was not only expensive in parts and labor—it also risked costly production delays.

A Material Upgrade: Tungsten Carbide Rings

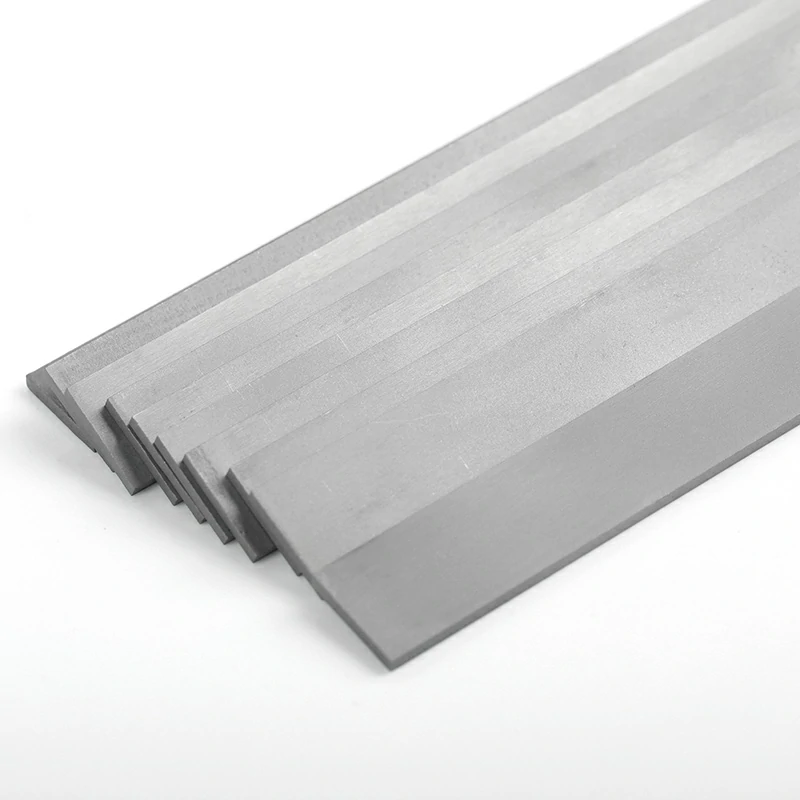

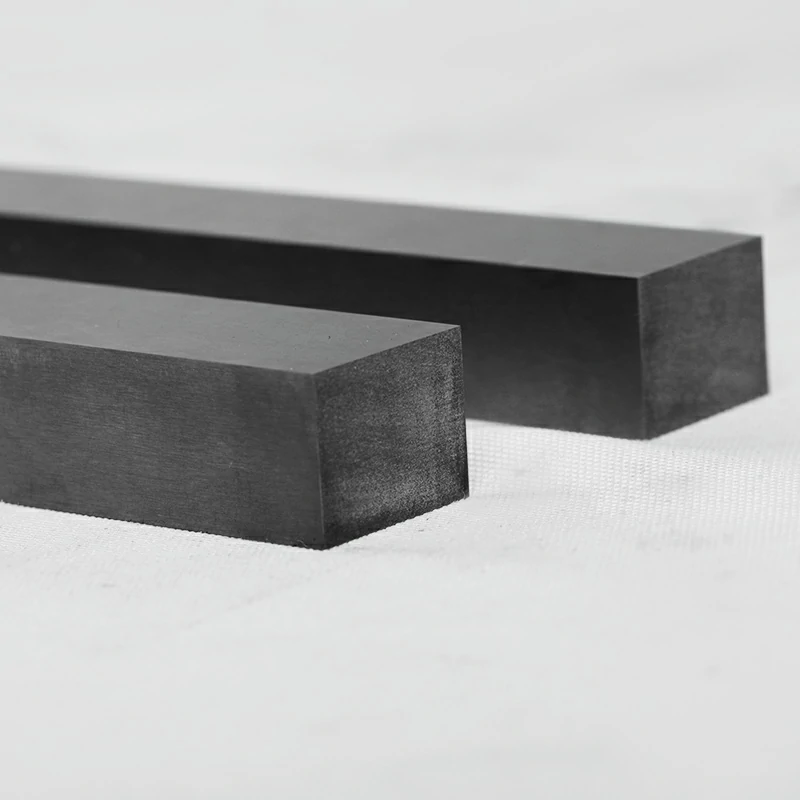

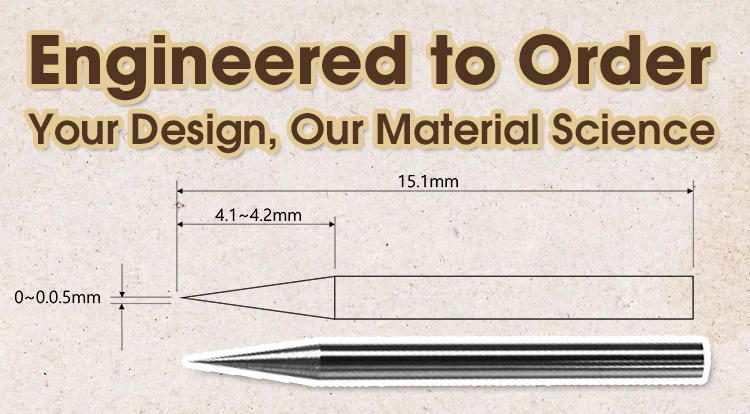

To break this cycle, the plant turned to HAO CARBIDE tungsten carbide rings. Manufactured through powder metallurgy from tungsten carbide and cobalt, these rings deliver:

Extreme Hardness (HRA ≥ 90) – far surpassing standard steels, making them nearly impervious to sand cutting.

Exceptional Abrasion Resistance – dozens of times more wear‑resistant than quenched steel.

Dimensional Stability – maintaining precise clearances over time to prevent vibration and seal failure.

Transformative Results: From 3 Months to 26+ Months of Service

After installation, performance improved dramatically:

Lifespan multiplied – sleeve service life increased from 3 months to over 26 months (8× longer, and counting).

Vibration remained low – even after two years, pumps ran as smoothly as when newly installed.

Significant savings achieved – reduced spare part use, maintenance labor, and downtime added up to over AUD 100,000 in annual savings per pump.

In Their Words

“Our cooling water pump previously needed inspection every 3 months. After switching to tungsten carbide rings, it has run flawlessly for over 26 months. We are extremely satisfied with the performance and savings.”

Conclusion: More Than a Part—A Reliability Breakthrough

This case underscores a clear industrial truth: when operating conditions overwhelm conventional metals, advanced materials like cemented carbide offer a decisive advantage. Upgrading to tungsten carbide rings isn’t just a component change—it’s a shift from reactive repairs to proactive reliability. By ending the wear cycle, these rings enable continuous, cost‑effective, and worry‑free operation.