How Carbide Jaws Achieve Both High Purity and Efficiency in Polysilicon Crushing

Writer: admin Time:2025-12-10 15:17:09

A leading Japanese manufacturer of advanced materials for electronics, ceramics, and new energy faced a critical bottleneck: their existing crushing jaws compromised between material purity and operational efficiency, limiting their production quality and cost-effectiveness.

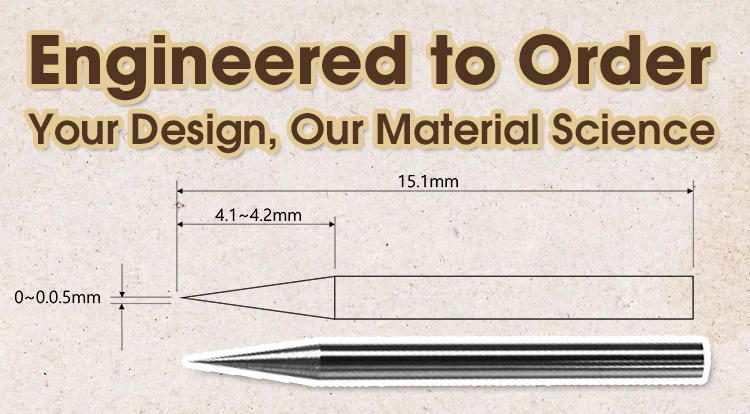

The Precision Solution

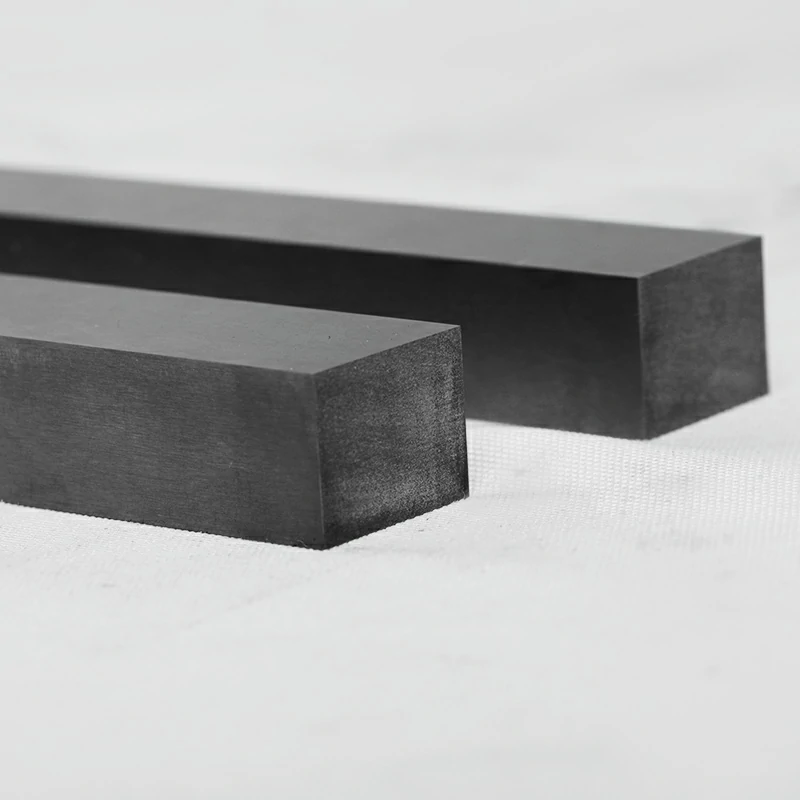

To meet their stringent requirements, we developed a specialized carbide jaw solution focusing on material integrity:

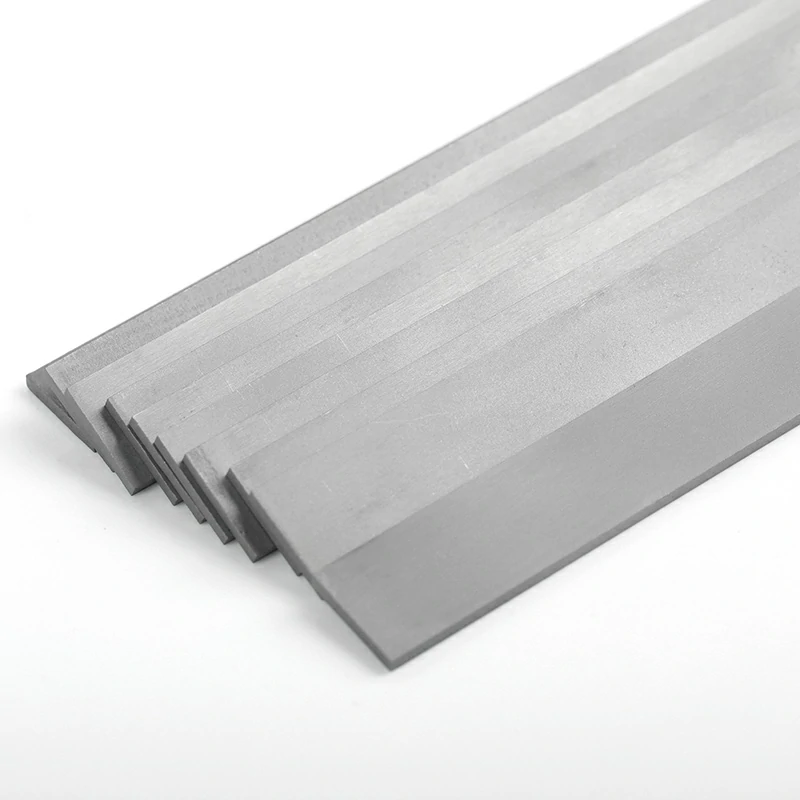

Ultra-Fine Grain Structure: Utilizing ultra-fine tungsten carbide powder for exceptional density and uniformity.

Advanced Sintering: Employing low-pressure sintering technology to minimize porosity and potential contamination sources.

Optimized Wear Resistance: The refined microstructure significantly reduces metal wear debris, safeguarding the purity of the crushed polysilicon.

Tangible Performance Gains

The results delivered measurable improvements across key metrics:

40% Longer Service Life for the jaw plates, drastically reducing replacement frequency.

Over 20% Increase in Production Line Uptime due to reduced maintenance.

Significant Reduction in Cost-Per-Ton of crushed material, thanks to lower energy and maintenance costs.

Client Endorsement

"Our supplier standards are extremely rigorous, with a focus on technical expertise and practical problem-solving. The team at Zhuzhou Jingzuan impressed us with their professionalism and the outstanding performance of their product. Your jaws not only solved our long-standing purity challenge but also delivered unexpected cost benefits through their exceptional durability. It was a perfect collaboration."

Partner for Demanding Applications

This case exemplifies how tailored carbide solutions can resolve core contradictions in precision manufacturing. We specialize in developing components that meet the dual demands of extreme purity and high productivity.

Facing similar challenges in your process? Contact us to explore a solution.