| GRADE | Properties and Applications |

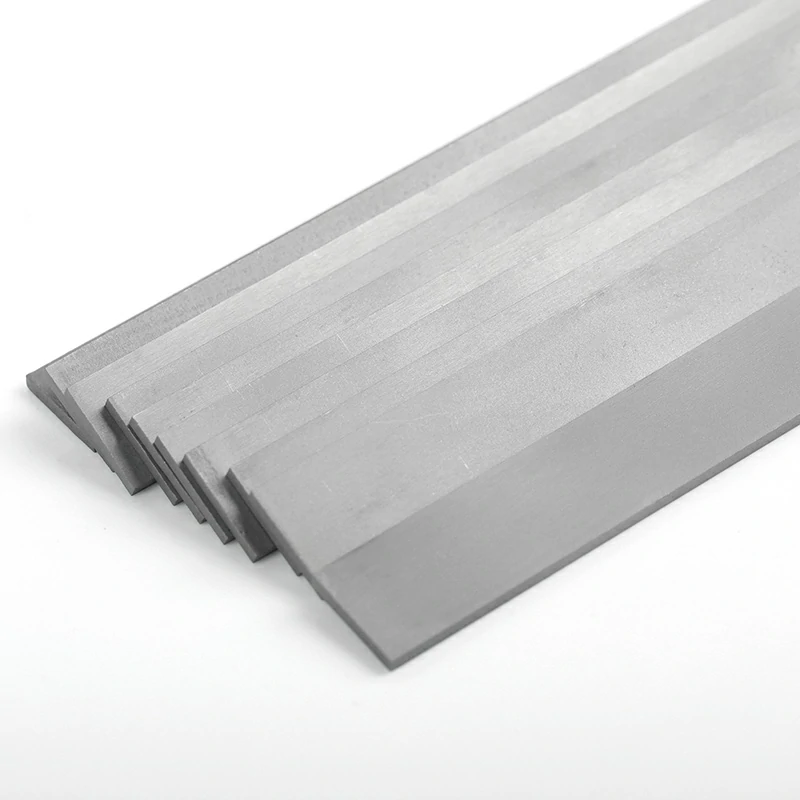

| JZ6 | Good wear resistance, used for hard wood, used for processing original wood, aluminum setion bar, brass rod and cast iron. |

| JZ6A | Has wear resistance higher than YG6, used for processing hard wood, original wood, aluminum setion bar, brass rod and cast iron. |

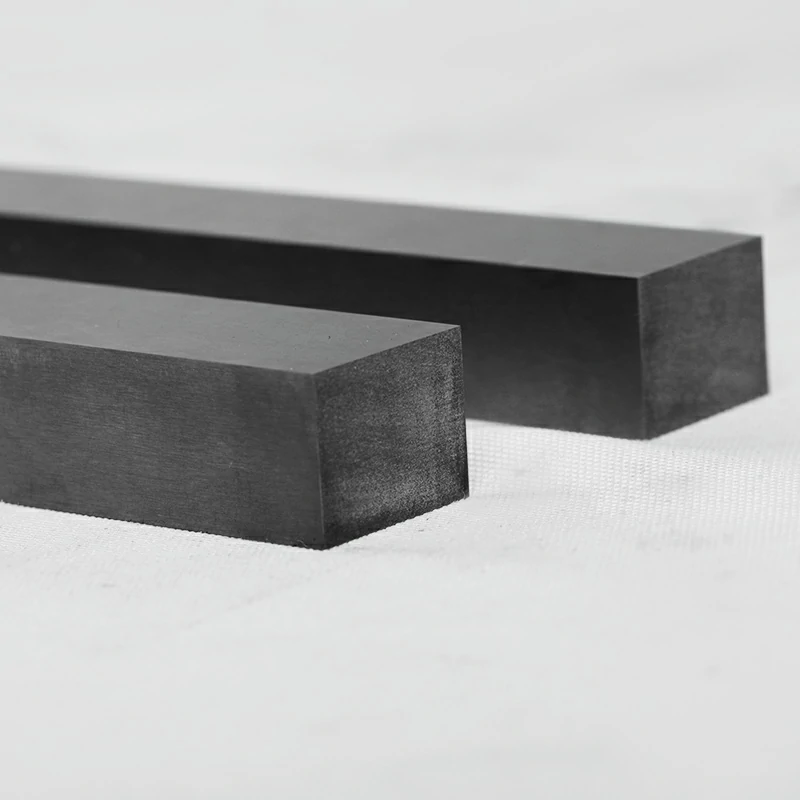

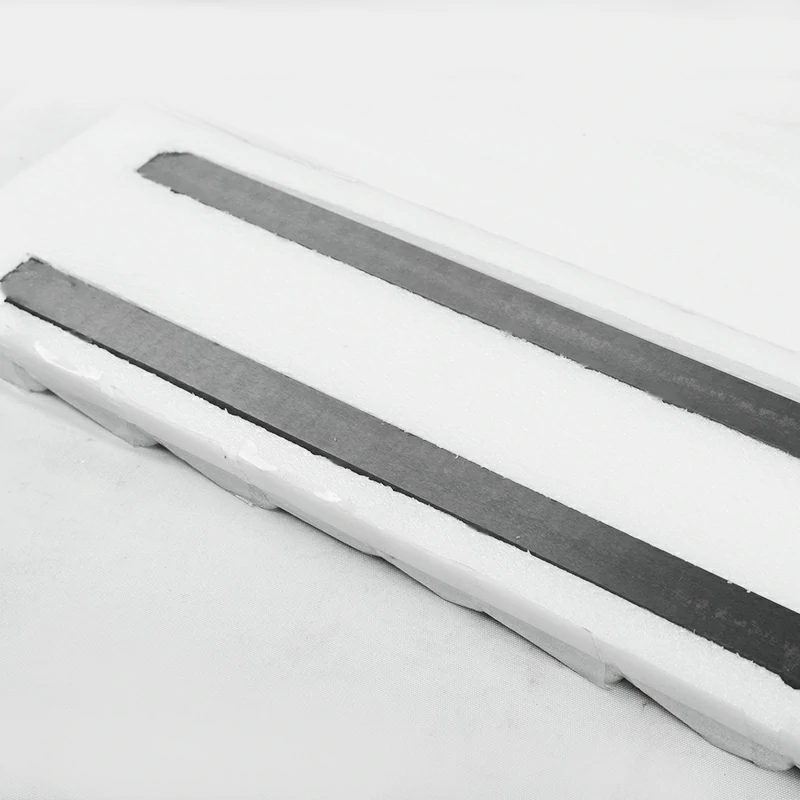

| JZ8 | Used for punch dies, stamping dies and wear resistance parts. |

| JZ2T | Fine carbide, high wear resistance, high bending strength, high resistance to bonding, high thermal strength. Machining of refractory alloys, stainless steel and high manganese steel, etc. |

| JZ10.2 | It suitable for making low and medium speed electronic class level dies, also applying in punching copper or aluminum strip. |