Product info

1. Hardness can reach to HRA 94, TRS ≥4000 N/mm²

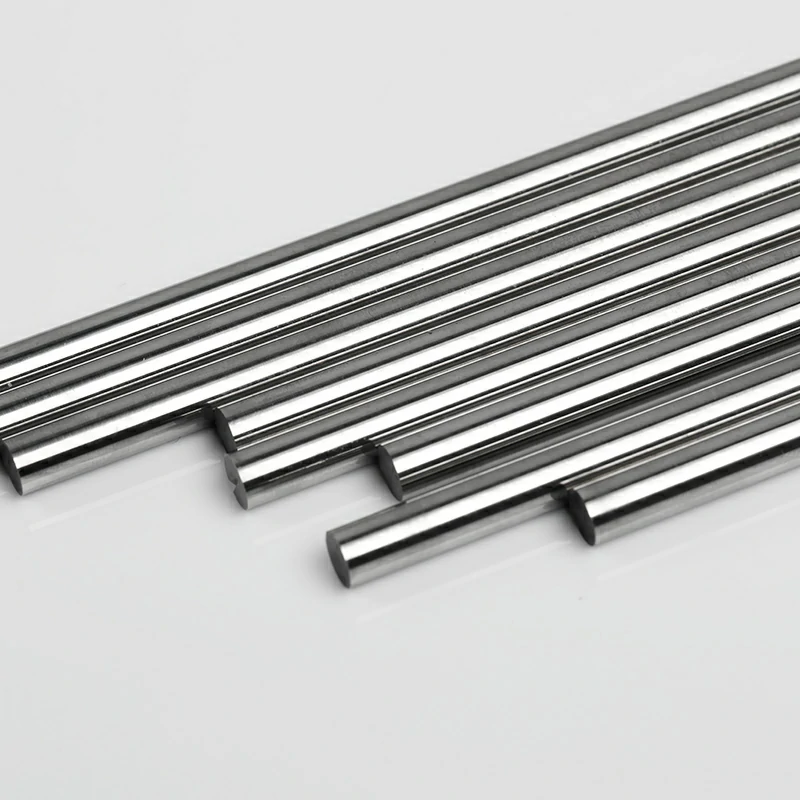

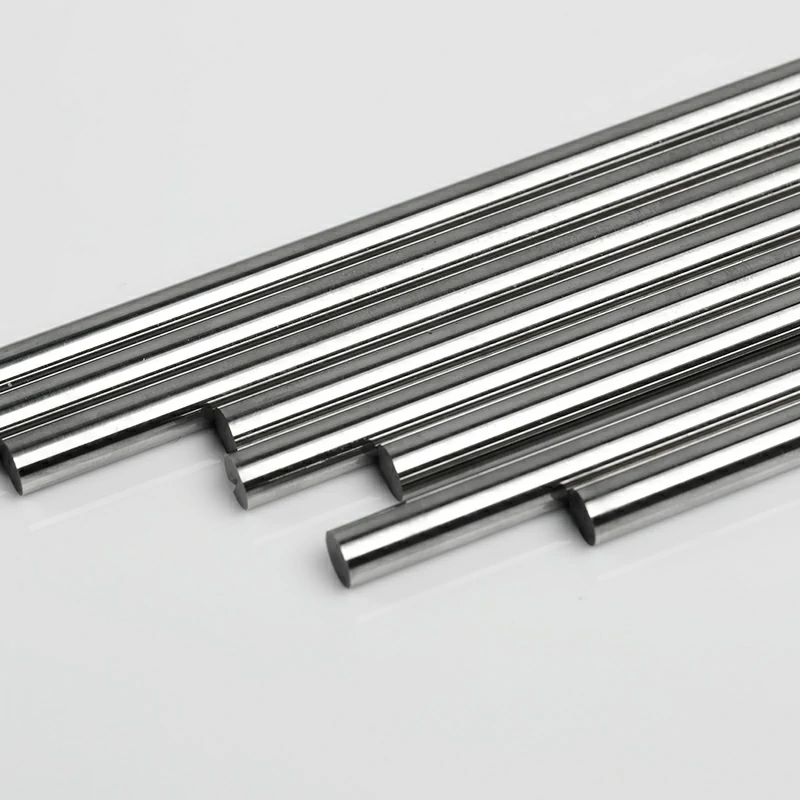

2. The sizes of the rodscan be customized as your requirements.

3. Blank rods and polished rods can be chosen.

4. The minimum diameter is φd 0.025mm and the tolerance can reach to ±0.001mm.

5. Common diameter from 1mm---30mm

6. Diameter tolerance: +0.3--0.8mm; length tolerance: +0.3--1.8mm

Product features:

1.Our cemented carbide rods use dry isostatic pressing machine and low press sintering technology,

which showed uniform distribution of cobalt magnetic, high hardness and bending strength.

2. Inner structure are more compact and well distributed in metallographic test.

3. It can reach a mirror effect surface after accurate grinding.

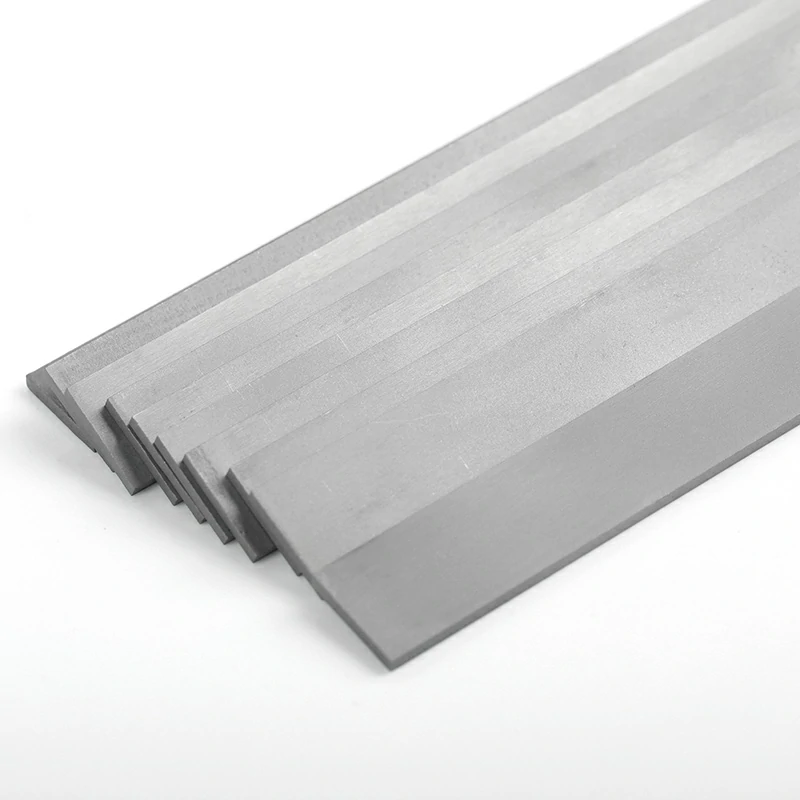

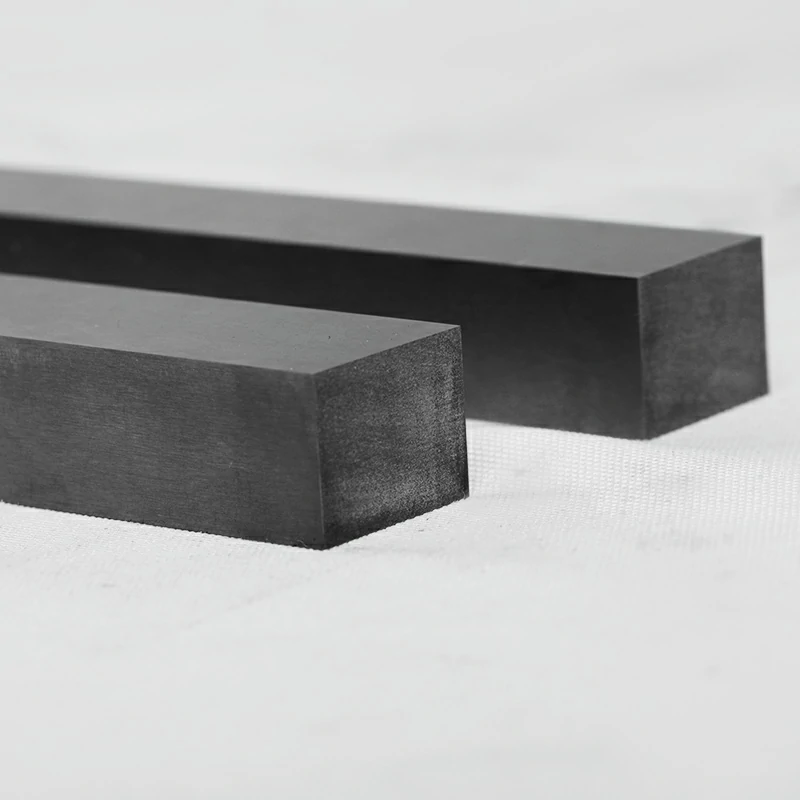

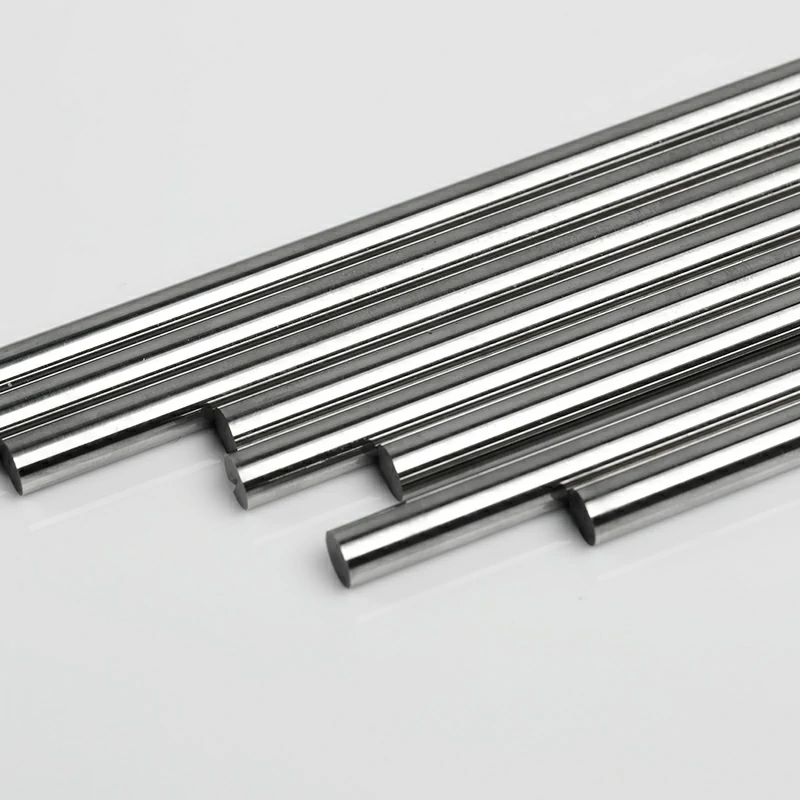

Product Dispaly

Specifications

| Cemented Carbide Grade | JZ06U | JZ08U | JZ12U | JZ12U-T | JZ10S | JZ10F |

| WC | % | 94 | 92 | 88 | 88 | 90 | 90 |

| CO | % | 6 | 8 | 12 | 12 | 10 | 10 |

| GRAIN SIZE | μm | 0.4 | 0.4 | 0.4 | 0.4 | 0.6 | 0.8 |

| DENSITY | G / c m³ | 14.85 | 14.65 | 14.25 | 14.20 | 14.40 | 14.40 |

| HRD | H R A | 94.0 | 93.6 | 92.5 | 93.0 | 92.1 | 91.8 |

| TRS | N / m m² | ≥4000 | ≥4000 | ≥3800 | ≥3800 | ≥3800 | ≥3800 |

| GRADE | The Grade Recommend |

| JZ06U | This tungsten carbide rod is with 0.4μm ultrafine particles and CO 6%. Be suitable for processing aluminum- magnesium alloy, glass fiber, carbon fiber, wood, hard plastic, etc. Recommend for making micro tools and drills. |

| JZ08U | This tungsten carbide rod is with 0.4μm ultrafine particles and CO 8%. Be suitable for processing resin, wood, titanium alloy, stainless steel, copper-aluminum alloy, composite material. Recommend making high speed drill, end mill, graver and micro-drill PCB with diameter less than 0.8mm. |

| JZ12U | This tungsten carbide rod is with 0.4μm ultrafine particles and CO 12%. Be suitable for semi-finishing and finishing process of stainless steel, mold steel and normal titanium alloy, etc. Recommend for making all types of high speed end mills, reamers and gravers. |

| JZ12U-T | This tungsten carbide rod is with 0 . 4 μ m ultrafine particles and CO 12 %, higher hardness . Be suitable for finishing process of stainless steel , mold steel and normal titanium alloy , etc . Recommend for making all types of high speed end |

| JZ10S | This tungsten carbide rod is with 0 . 6 μ m Sub - micron particles and CO 10 %, which is widely used in cutting tools . Be suitable for rough finishing , semi - finishing and finishing of mold steel , grey cast iron , austenitic stainless steel and heat - resistant alloy . Recommend for making normal drill and end mill |

| JZ10F | This tungsten carbide rod is with 0 . 8 μ m Sub - micron particles and CO 10 %. Be suitable for rough finishing and semi - finishing of normal steel , cast iron and stainless steel . Recommend for making normal drill and end mill |

| Be processed material | Suitable grand |

| First chioce | Wear-resisting | High toughness | High toughness |

| Low-alloy steel(intensisty700 N/mm²) | J Z 1 0 S |

|

| J Z 5 |

| Alloy steel(intensisty700 N/mm²) | J Z 1 0 S | J Z 5 |

| J Z 5 |

| Stainless steel | J Z 1 0 S | J Z 5 |

|

|

| Csst iron |

| J Z 0 6 U |

|

|

| Aluminum alloy,Copper,Plastic | J Z 0 6 U |

|

| J Z 5 |

| Graphite | JZ06U+COATING |

|

|

|

| Titanium alloy,Heat-resisting alloy | J Z 1 0 S | J Z 5 |

|

|

| Hardened steel(hardness? 60HRC) | J Z 1 2 U | J Z 1 2 U - T |

|

|

| Reamer | J Z 0 6 U |

|

|

|

| Flushes the needle,Drift,Mold | J Z 1 0 F |

|

|

|

| PCB drill bit,Aluminum/copper sheet | J Z 0 6 U |

|

|

|

| Drill bit | J Z 1 0 S |

| J Z 5 |

|